At the end of May, I was lucky enough to get the opportunity to talk to David Cebon about his Electric Road System project on our Journey to Zero podcast.

David is a Professor of Mechanical Engineering at Cambridge University, the Director of the Centre for Sustainable Road Freight, and a Fellow of the Royal Academy of Engineering. He has co-authored many papers on HGVs and has a strong focus on sustainability in the road freight sector – so an incredibly knowledgeable man in this sector.

David is currently setting out the case for a nationwide rollout of Electric Road Systems in the UK through the 2030s as the only real plausible solution to decarbonise our long-haul freight vehicles.

In episode five of the Journey to Zero podcast, David shares his expertise on:

• What an Electric Road System (ERS), or eHighway, actually is

• How an eHighway could be used in the UK to decarbonise most of our long-haul vehicles

• Comparing eHighways to other options such as Hydrogen, Biogas, and Battery Electric Trucks

• How long it would take to implement ERS in the UK

• How much it could cost and how it would be funded

• The cost of the eHighway-compatible trucks

• What the future will look like for our commercial vehicles

• An exclusive about a potential demo here in the UK!

If you don’t know what an Electric Road System is, they are very likely to be a big part of our future in the commercial vehicle industry. So, do check out this podcast with David (or carry on reading this article) to stay ahead of the game.

With an Electric Road System (ERS), the idea is that you take the electrons to the truck through a wire instead of carrying them in a box, in a big battery.

That has a lot of advantages. For a start, it’s a lot lighter. It’s certainly cheaper as far as the vehicle is concerned as batteries are expensive, they’re heavy and they take up a lot of space in large trucks. Batteries also contain rare and expensive materials.

The real issue is for long-haul trucks, we’ve got to store a lot of energy and you need a lot of power. This [the ERS] is much more effective way to solve the problem.

The idea with ERS is that you build infrastructure which consists of overhead catenary cables that go along most of the motorways and A-roads.

The trucks have a mechanism called a pantograph, as you see on top of an electric train. It’s an active pantograph so it can be put up and down quickly and it can even be deployed automatically.

Picture from Scania’s YouTube video: World’s first electric road opens in Sweden (June 2016)

So, the truck has the pantograph on the top and it picks up electricity from the overhead wire as it runs along. The wire is most likely to be in the slow lane on the motorway, so you can imagine all the trucks travelling in the left-hand lane in the UK, picking up the electricity from the overhead wire.

The electricity goes straight into what’s called an inverter, and from the inverter, directly into the electric motor of the truck.

That is the most efficient way that you can use electricity, you don’t even have to charge a battery. It’s the most bang for the buck that you can get using renewable electricity. So, it’s very efficient, which results in low cost.

Now, the vehicles also have relatively small batteries. When I say relatively small, they’re batteries of the same size as an electric car. For example, a 70, 80 or 90 kilowatt-hour battery. That’s the same kind of size and weight as a fuel tank that this truck would have anyway.

What that battery does is allows the truck to drive happily for 30 to 50 miles on battery power. That means that trucks can pass one another when overtaking, or they can go through a long tunnel, or under a bridge without having to have a continuous wire. The catenary wire can have a break in it if necessary, such as at complicated motorway junctions.

It also means that the electric trucks can drive from the end of the motorway to the depots where they’re going to drop off their loads. There tends to be small distances between those depots and motorways. A large proportion of the UK’s road freight depots are located near to junctions on the strategic road network.

Then, you have to join that with the rest of the logistics system. Since many of the depots are located at the edge of town, you can run battery electric vehicles from those depots to do the urban deliveries, home deliveries, the deliveries to convenience stores – the journeys where battery electric vehicles are fine because the battery doesn’t have to be too big.

The combination of electric roads on strategic motorways in the country, and battery electric vehicles running into cities actually would decarbonise pretty much all of the UK’s road freight. Well, electrify it, not decarbonise it, you need to use green electricity. But that’s something the electricity sector is looking after.

There are a number of reasons. There are three possible technologies you can use on electric roads. There are the overhead catenary cables, then there are two possible in-road solutions.

One of which is inductive pads in the roads, like your electric toothbrush, so you don’t have to have contact. You have a pickup in the vehicle and as it goes over each pad it gets some electricity on board. In order to deliver enough power, you need almost continuous inductive pads along the road.

Now, putting stuff in the road is incredibly challenging. My view is that it is a fatal flaw, because everything that you’ve got in the road is getting pounded by thousands, or tens of thousands of truck axles, every day. It’s a really harsh environment.

Picture from CNET article: Qualcomm’s inductive charging road could pave the way to new EVs

I know that because earlier in my career I did quite a lot of work on systems embedded in the road, such as sensors, and it was incredibly difficult to make a durable system that gets pounded by trucks.

So, if you’ve got these induction pads every couple of metres along the road, you really are building a terrible maintenance problem. I don’t personally see that specific engineering problem ever being solved. I think it’s just too hard to deal with.

The other possibility, which is being investigated in Sweden, is more like what you would call a ‘Scalextric’ solution. It’s where you have a conductive track in the middle of the road.

Picture from Future Car’s article: Sweden Deploys World’s First EV Charging Road

Again, you’d have to have something in the road. With this system, you’d have more issues with stuff getting stuck in there, like snow and mud, and you have the complexities of vehicles passing one another having to disconnect and connect. There’s a set of deployment issues there, which are all much easier with the over-catenary wires and pantograph.

Let me just make one other point, and that is that overhead catenary cables have been used in the railway industry for a century and there are dozens of international standards which govern their deployment. Therefore, you’re starting from a technology that is well understood and well standardised. I’ve been involved in standards committees, and they typically take ten years, or maybe twenty years, to agree on a new standard. The idea that we’re going to come to standards for these technologies that are buried in the road in any short time is a serious issue.

Therefore, for all of those reasons, I believe the overhead catenary cables are by far the most likely to be successful of the ERS technologies.

Well, there’s a lot of interest in using gas to power trucks. You can use compressed natural gas, or you can use compressed biomethane.

If you use biomethane, there’s something like a 70-80% carbon emissions reduction, and that is pretty good.

In terms of what you can do now, that is a pretty effective thing to do. There are quite a lot of companies that are using biomethane. Unfortunately, I don’t think that is the ultimate solution for trucks. If we want to get to net zero, we have to have a solution that everybody can implement, and there’s simply not enough biomethane to go around for the UK, let alone the rest of the world. A very small proportion of the natural gas in the UK is biomethane at the moment.

Another issue is there are other modes of transport that will rely on biofuels, particularly ships and planes, and they can’t be electrified the same way trucks can. There’s a very strong case to say that biofuels should be reserved for ships and planes.

Hydrogen is being considered for long-haul transport. Volvo and Mercedes have recently started a joint venture to make fuel cells for trucks.

I am very highly sceptical about using hydrogen for transport for a whole series of reasons.

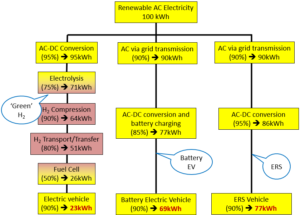

The main one is the hydrogen processes are very inefficient. They waste a lot of energy, for example when you do electrolysis to make hydrogen from water, you loose 25% of the energy. You then have to compress the hydrogen and store it, because hydrogen’s a really difficult substance to handle. It has the smallest molecules which leak out of things and damage steel pipes.

Then, you have to put it through a fuel cell, and a fuel cell is only about 50% efficient, because it has to satisfy the second law of thermodynamics which limits the efficiency. Just like a truck diesel engine can never be more than around 45% efficient.

When you put all those inefficiencies together for hydrogen, what you find is that you get about 23% (or 23 kWh out of 100 kWh) of the energy out of the process. So, you’ve thrown away 77% of the energy, that means that it costs you around three and a half times more in energy terms to drive a hydrogen truck than to drive an electric road system truck.

See graph below for visual explanation:

The cost to operators for fuel is going to also be three and half times more. As is turns out, a hydrogen fuel cell truck is going to be much more expensive than the eHighway truck as well.

A hydrogen truck and an eHighway truck are the same platform. They’re both electric vehicles. The both have similar sized batteries. (The Mercedes fuel cell vehicle will have a 70kWh battery). They both have an electric motor.

For a hydrogen vehicle, you add a fuel cell, hydrogen storage and all of that that comes with hydrogen handling, and hydrogen fuel cells are currently quite expensive bits of kit.

Alternatively, you can put the overhead pantograph mechanism on that truck, which is a low cost piece of mechanical equipment. It’s just lifts up the collector about a metre to make contact. It’s a much cheaper system than hydrogen fuel cells and hydrogen tanks and all that stuff.

This makes the electric road system truck a much more attractive option to logistics operators. As well as that, is uses less than a third of the energy of a hydrogen fuel cell vehicle. So running it is far cheaper.

I can’t see how you can make sense of a hydrogen fuel cell vehicle in comparison with an electric road system vehicle.

The big difference is in the cost of infrastructure, of course. But it’s not as expensive as you might think. In fact, the cost of doing all the roads you would want to do in the UK is less than the cost of the Department of Transport’s budget for roads for the next 5 years (£27 billion for 2020-2025). It would cost around £20 billion to install ERS for all the roads we need and our calculations indicate that it could be completed in 15 years from 2025 to 2040.

If the UK wants to decarbonise all its trucks, which it can do in about 15 years, then by spending a budget less than the current roads budget (much less actually over that 15 year period), it could deploy the electric road system across the country.

The vehicles would be far cheaper for the operators, far cheaper in energy costs, and far cheaper to run.

This is not just about promoting eHighways, what this is about is asking; “How do we decarbonise the UK’s logistics in the most efficient, quickest, and most effective way?”

We’ve looked at this in some detail, and every way that you look at it, the Electric Road System comes out as being the answer.

The Department for Transport is planning to run a couple of big demonstrator projects. We think that there’s going to be a hydrogen demonstrator project and an electric roads demonstrator project.

Innovate UK recently had a call for a proposal’s feasibility study in advance of these large-scale demos, and I’m part of a team that’s put together a proposal. I’m hopeful we might be successful, but we don’t know yet.

We think it’s fairly likely that a demonstrator project will go ahead, and that’s our first phase of deployment.